Workshop voices first

Fitment notes, safety warnings and tips come from real jobs with real deadlines, not from generic descriptions copied between brands.

Behind the catalog

Torque & Parts started as a set of spreadsheets in a small workshop that was tired of wrong deliveries, confusing names and missing small parts that stop a job cold.

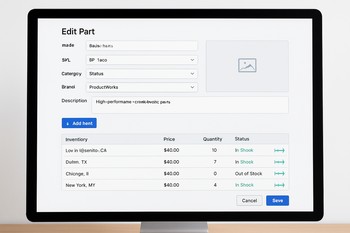

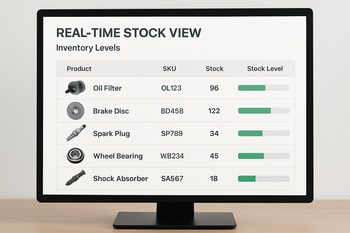

Today those same notes and patterns power a catalog that respects your time: clear photos, realistic stock and support that speaks the same language as your tools.

The goal is not to create more portals. It is to keep one clear loop that starts with a job and ends with a car leaving the workshop on time.

Torque & Parts is maintained by mechanics, parts specialists and drivers who spend more time in garages and on the road than in meeting rooms.

Fitment notes, safety warnings and tips come from real jobs with real deadlines, not from generic descriptions copied between brands.

The people answering questions have changed discs, traced wiring faults and rebuilt suspension, so they understand why details matter.

The catalog is built for people who think in jobs, tools and deadlines, not in abstract part codes.

Drivers who care about their cars and prefer to do as much as possible themselves, but still want clear guidance and the right parts.

Workshops that need predictable deliveries, realistic stock and support that understands the pressure of a full day of bookings.

People who manage several vehicles and need clean overviews of upcoming jobs and parts without drowning in documents.

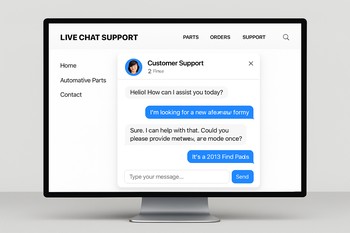

Support is not a separate world. It is a continuation of the same workshop conversation you already have with colleagues.

Ideal for sending photos of parts, connectors and axle plates.

Talk through edge cases and unusual symptoms step by step.

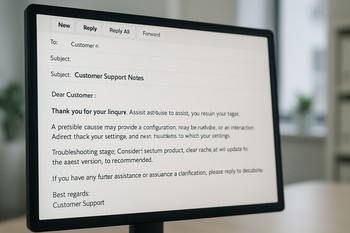

Keep written confirmations of specs, alternatives and lead times.

Part data only earns its place in the catalog when it survives real jobs in real garages. That is why updates come from the same people who use the parts.

In a busy workshop, the catalog is never the star of the show. It simply sits in the background, quietly solving questions so jobs keep moving.

Cars arrive, notes are taken and first shortlists are built while coffee is still warm.

Support helps confirm tricky fitment details before afternoon work continues.

Parts for tomorrow are queued, so the next day starts with tools, not phone calls.

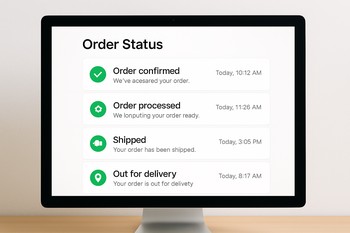

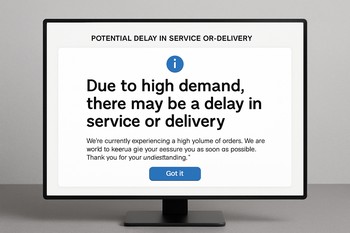

Every decision — from how a part is described to how a delay is communicated — is checked against a short list of principles.

The catalog is not tied to one country or one type of driver. It pays attention to how cars age in cities, on long highways and on rougher local roads.

Stop-start driving that wears out brakes, clutches and cooling systems faster.

Suspension and steering components that handle potholes and rougher surfaces.

High-mileage parts focused on quiet operation and steady fuel economy.

The catalog is designed to be honest about stock, timing and mistakes, so you can make decisions with a clear picture instead of guessing.

Short, direct updates instead of long paragraphs that hide what really changed.

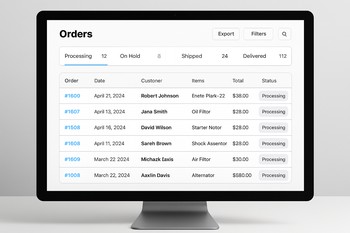

If something slips, the new date is visible in the same place you track every order.

Every message suggests what you can do now: wait, swap a part or split deliveries.

Even with careful checks, surprises still happen. The important part is how fast you can get back to the job without blaming anyone for trying.

Instead of waiting for rare “big releases”, Torque & Parts evolves through small, constant adjustments guided by what garages report every day.

Regular tweaks to which cars a part suits, based on real installs and returns.

Fresh combinations whenever mechanics notice patterns in their weekly work.

Descriptions rewritten when support sees the same question asked too often.

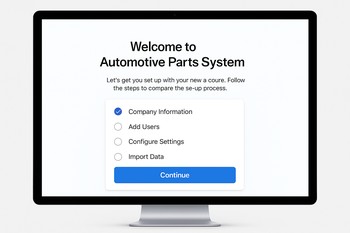

Most garages do not have time for long rollouts. Torque & Parts is meant to slot into a normal week, not replace it.

A catalog can never replace solid workshop habits. It can, however, keep pointing back to them at the right moments.

Critical fasteners are marked with notes to check the correct tools and values.

Warnings explain why a step matters instead of just telling you “do not skip this”.

Garages can add their own safety notes alongside catalog information.

Mechanics and drivers rarely sugar-coat their words — and that is exactly the kind of feedback that keeps the catalog useful.

“If a part needs a special tool or trick, say it up front. Do not hide it in tiny text.”

Front-line mechanic“Tell me which option most people pick for this car. That helps when I am in a hurry.”

Workshop owner

Torque & Parts does not chase trends for their own sake. New features join the catalog only when they remove friction in the way garages already work.

Upcoming tools make it easier to see which jobs depend on the same critical parts.

Photos and diagrams help confirm parts before you even open the box.

Notes and past choices travel with a vehicle instead of getting lost in paperwork.

Suppliers, warehouses and courier partners all see the same priority: parts that arrive on time and match what the catalog promises.

You do not have to change everything at once. Start as small as you like and grow only when the catalog has earned its place on your bench.

Whatever you choose, Torque & Parts is designed to be a quiet helper in the background — not another system that gets in the way of real work.